High-Quality Sticker Printing and Cutting Machine for Your Needs

By:Admin

In a world where visual communication is becoming increasingly important, the demand for high-quality stickers is on the rise. As a response to this growing need, {Company Name} is proud to introduce their latest innovation in sticker printing and cutting technology: the new {Need to remove brand name} machine. This cutting-edge machine is set to revolutionize the sticker printing industry, offering a range of features and benefits that are sure to impress both businesses and individuals alike.

The {Need to remove brand name} machine is designed to provide a seamless and efficient sticker printing and cutting process. Equipped with the latest printing technology, the machine is capable of producing vibrant and eye-catching stickers that are sure to grab the attention of any audience. Whether it's for personal use or for business advertising, the {Need to remove brand name} machine can handle a wide range of sticker printing needs with ease.

One of the key features of the {Need to remove brand name} machine is its precision cutting capabilities. With state-of-the-art cutting technology, the machine is able to produce clean and accurate cuts, ensuring that each sticker is perfectly shaped and ready for use. This level of precision is essential for businesses that require professional-looking stickers for their products, packaging, or promotional materials.

In addition to its impressive printing and cutting abilities, the {Need to remove brand name} machine is also designed with user convenience in mind. The intuitive interface makes it easy to navigate and operate, allowing users to quickly and effortlessly create their own custom stickers. This user-friendly design makes the machine suitable for a wide range of users, from small businesses to hobbyists and enthusiasts.

Furthermore, the {Need to remove brand name} machine is built with durability and reliability in mind. The robust construction and high-quality components ensure that the machine can handle high-volume printing and cutting tasks without compromising on performance. This makes it an ideal investment for businesses that require a dependable and long-lasting sticker printing solution.

{Company Name} is committed to providing its customers with the latest and most innovative solutions in the field of sticker printing and cutting. The introduction of the {Need to remove brand name} machine is a testament to this commitment, and the company is confident that it will be a game-changer in the industry. With its cutting-edge technology, user-friendly design, and exceptional performance, the {Need to remove brand name} machine is set to become the go-to choice for anyone in need of high-quality stickers.

As the demand for stickers continues to grow, {Company Name} is proud to be at the forefront of this industry, offering innovative solutions that meet the needs of modern businesses and individuals. With the introduction of the {Need to remove brand name} machine, the company is once again demonstrating its dedication to pushing the boundaries of sticker printing and cutting technology.

In conclusion, the {Need to remove brand name} machine represents a significant advancement in sticker printing and cutting technology. With its impressive features and capabilities, it is set to become a must-have tool for businesses and individuals looking to create high-quality custom stickers. {Company Name} is excited to bring this new innovation to the market and is confident that it will make a positive impact on the industry.

Company News & Blog

Top 10 Cutting Sticker Machines for DIY Projects in 2022

The Cutting Sticker Machine is set to revolutionize the sticker and label industry with its cutting-edge technology and innovative design. The machine, produced by a leading manufacturer in the industry, promises to provide a fast, efficient, and cost-effective solution for businesses looking to streamline their sticker production process. With its user-friendly interface and high-precision cutting capabilities, the Cutting Sticker Machine is a game-changer for businesses of all sizes.The company behind the Cutting Sticker Machine has been a pioneer in the sticker and label industry for over two decades. With a commitment to innovation and excellence, they have consistently delivered high-quality products and solutions to meet the evolving needs of their customers. The launch of the Cutting Sticker Machine is a testament to their dedication to providing cutting-edge technology that empowers businesses to enhance their production processes and elevate their brand presence.The Cutting Sticker Machine boasts a range of impressive features that set it apart from traditional sticker cutting methods. Its automatic feed and cutting system allow for continuous, uninterrupted operation, saving businesses valuable time and resources. The machine's high-precision cutting capabilities ensure clean, accurate cuts, resulting in a professional finish for every sticker and label produced. Additionally, its compatibility with a variety of materials, including vinyl, paper, and film, makes it a versatile and adaptable solution for a wide range of applications.One of the standout features of the Cutting Sticker Machine is its user-friendly interface, which is designed to streamline the production process and minimize the need for manual intervention. The machine's intuitive controls and automated functions make it easy for operators to set up and execute cutting jobs with minimal training or experience. This not only improves overall efficiency but also reduces the risk of human error, ensuring consistent and reliable results with every use.Furthermore, the Cutting Sticker Machine is equipped with advanced software that allows for precise design customization and optimization. This feature enables businesses to create unique and intricate designs for their stickers and labels, giving them a competitive edge in the market. Whether it's for branding, packaging, or promotional purposes, the machine's ability to accommodate complex designs and patterns opens up a world of possibilities for businesses to express their creativity and individuality.In addition to its cutting-edge technology and innovative design, the Cutting Sticker Machine is also a cost-effective solution for businesses. Its efficient operation and minimal maintenance requirements help reduce operational costs, making it a smart investment for businesses looking to improve their production processes without breaking the bank. The machine's ability to deliver high-quality results consistently also means that businesses can save money on reworks and wastage, ultimately boosting their bottom line.The launch of the Cutting Sticker Machine marks a significant milestone for the company, further solidifying its position as a leader in the sticker and label industry. With its unparalleled technology, user-friendly design, and cost-effective benefits, the machine is poised to become the go-to solution for businesses looking to elevate their sticker production capabilities. As the demand for personalized and high-quality stickers and labels continues to grow, the Cutting Sticker Machine is well-positioned to meet and exceed the needs of businesses across various industries.In conclusion, the Cutting Sticker Machine, developed by a renowned manufacturer with a long-standing reputation in the industry, represents a game-changing solution for businesses seeking to enhance their sticker production processes. With its cutting-edge technology, user-friendly interface, and cost-effective benefits, the machine is set to empower businesses to optimize their operations and elevate their brand presence. As the industry continues to evolve, the Cutting Sticker Machine stands out as a progressive and innovative solution that is well-equipped to meet the changing needs of businesses in the sticker and label sector.

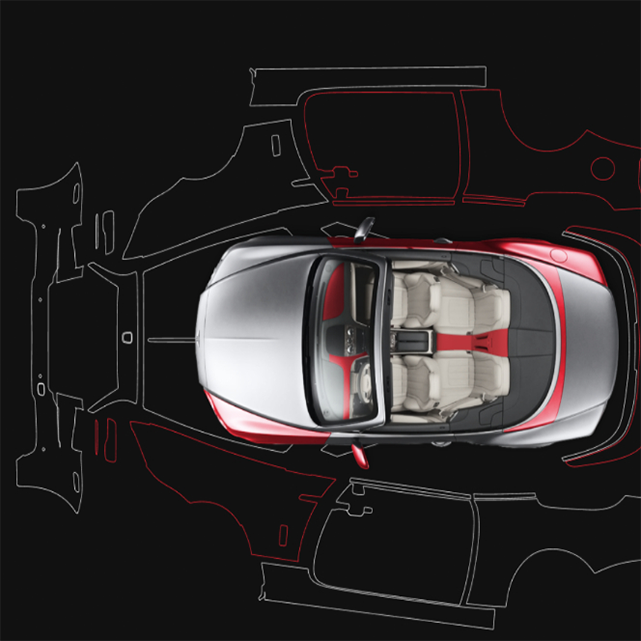

Understanding the PPF Cut Program and Its Impact on Consumers

[Ppf Cut Program], a leading automotive company known for its innovative products and services, has recently announced the launch of their new program designed to enhance the performance of non-brand vehicles. This new program, called Ppf Cut, is a breakthrough initiative that aims to provide high-quality products and services to customers who own vehicles that are not manufactured by the company.[Ppf Cut Program] is a well-established company that has been in the automotive industry for over 15 years. They are recognized for their commitment to excellence and have built a strong reputation for delivering top-notch products and exceptional customer service. Their team of experts is dedicated to providing innovative solutions that meet the needs of their customers and exceed their expectations.The Ppf Cut Program is a testament to the company's ongoing dedication to innovation and customer satisfaction. This new program is designed to provide a range of services and products that cater to the specific needs of non-brand vehicle owners. Through this program, customers can expect to receive high-quality products and services that are tailored to their individual requirements.One of the key features of the Ppf Cut Program is its focus on paint protection film (PPF) installation. PPF is a transparent film that is applied to the surface of a vehicle to protect its paint from scratches, rock chips, and other forms of damage. This program offers customers the opportunity to have PPF installed on their vehicles by a team of highly skilled and experienced technicians. The Ppf Cut Program uses state-of-the-art technology and the highest quality materials to ensure that customers receive the best possible protection for their vehicles.In addition to PPF installation, the Ppf Cut Program also includes a range of other services designed to enhance the performance and appearance of non-brand vehicles. This includes paint correction, ceramic coating, window tinting, and more. These services are carried out by a team of professionals who are dedicated to delivering outstanding results and exceeding customer expectations.Furthermore, the Ppf Cut Program offers a tailored approach to customer service, with a personalized consultation and assessment for each vehicle. This ensures that customers receive the most suitable products and services for their specific needs. The program also includes a warranty to provide customers with peace of mind and assurance of the quality of the products and services provided.The launch of the Ppf Cut Program represents an exciting development for [Ppf Cut Program]. It demonstrates the company's commitment to meeting the needs of all automotive enthusiasts, not just those who own vehicles manufactured by the company. By offering a range of high-quality products and services for non-brand vehicles, [Ppf Cut Program] is further solidifying its position as a leader in the automotive industry.As the automotive industry continues to evolve, [Ppf Cut Program] is dedicated to staying at the forefront of innovation and customer satisfaction. The Ppf Cut Program is a prime example of their ongoing efforts to provide cutting-edge solutions for all customers, regardless of the make or model of their vehicles. With this new program, [Ppf Cut Program] is set to make a significant impact on the automotive aftermarket industry and deliver unparalleled value to non-brand vehicle owners.

Free Download Cutting Plotter Software for Your Business

Cutting plotter software enables users to create precise and intricate designs for cutting various materials such as vinyl, paper, fabric, and more. The software provides users with the tools needed to create, edit, and customize designs for their cutting projects. With the growing popularity of cutting plotters for various applications, the demand for reliable and user-friendly cutting plotter software has also surged.To meet this demand, {Company Name} has announced the release of their cutting plotter software, available for free download. This software is designed to provide users with a seamless and efficient experience in creating designs for their cutting projects. The user-friendly interface and advanced tools make it suitable for both beginners and experienced professionals in the industry.According to a spokesperson from {Company Name}, "We understand the importance of having high-quality software to accompany cutting plotters. Our cutting plotter software is designed to meet the needs of our customers and provide them with the tools they need to bring their creative visions to life."The {Company Name} cutting plotter software offers various features such as:1. Design Tools: The software provides users with a wide range of design tools to create and customize their designs. This includes the ability to add text, shapes, and patterns to their designs.2. Compatibility: The software is compatible with a variety of file formats, allowing users to import their designs from various sources and platforms.3. Precision Cutting: The software ensures precision cutting by providing users with the ability to adjust settings such as blade depth, speed, and pressure.4. Ease of Use: With an intuitive interface, the software is easy to navigate, making it suitable for users of all skill levels.The release of {Company Name} cutting plotter software comes as a welcome announcement for the cutting plotter community. As more individuals and businesses explore the possibilities of cutting plotters for their projects, having reliable software is crucial to their success.{Company Name} is a leading provider of cutting plotter solutions, offering a range of cutting plotters designed for various applications. Their cutting plotter software is the latest addition to their suite of products, further solidifying their position in the industry.With the free download of their cutting plotter software, {Company Name} aims to provide a valuable resource for individuals and businesses looking to explore the world of cutting plotters. By offering a user-friendly and feature-packed software, they hope to empower their customers to unleash their creativity and achieve exceptional results with their cutting projects.The {Company Name} cutting plotter software is now available for free download on their website, and it is compatible with a wide range of cutting plotter models. As the industry continues to evolve, {Company Name} remains committed to providing cutting-edge solutions that cater to the needs of their customers.In conclusion, the release of {Company Name} cutting plotter software marks an important milestone for the cutting plotter community. With its user-friendly interface, advanced features, and compatibility with a variety of cutting plotter models, the software is set to become a valuable asset for individuals and businesses alike. As the demand for reliable cutting plotter software continues to grow, {Company Name} has positioned itself as a leading provider of cutting plotter solutions, with a focus on empowering their customers to achieve exceptional results in their cutting projects.

Custom Vinyl Decal Cutter Printer for Elegant Home Decorating

Vinyl printing has taken the decoration and advertising industry by storm, making it one of the most popular printing methods today. Having the right vinyl printer cutter is crucial to achieving the perfect prints, and the right combination of features can make all the difference.A vinyl printer cutter is a device that prints and cuts vinyl sheets to produce customized decals, stickers, signs, and banners. These machines use a combination of printing and cutting technologies to create intricate designs and shapes that are impossible to achieve with manual tools.When choosing a vinyl printer cutter, there are several factors to consider. The first is the size of the machine. Smaller models are suitable for small businesses or hobbyists, while larger ones are ideal for larger printing projects.The second factor is the printing technology used. There are two main types of printing technologies used in vinyl printers: inkjet and thermal transfer. Inkjet printers are more versatile and can handle a wider range of materials, while thermal transfer printers are more accurate and produce higher quality prints.Another important factor to consider is the cutting technology used. Some vinyl printer cutters use a drag knife system, while others use a laser or rotary blade. A drag knife system is ideal for cutting simple shapes and designs, while a laser or rotary blade is better suited for more complex designs.Other factors to consider include the software used to design and print the vinyl, the speed and precision of the machine, and the level of support provided by the manufacturer.Overall, there are many great vinyl printer cutters available on the market today. When choosing a machine, it is important to consider the size, printing technology, cutting technology, software, speed, precision, and support provided by the manufacturer.If you're in the market for a vinyl printer cutter, be sure to do your research and choose a machine that meets your specific needs and requirements. With the right machine, you can create stunning, customized vinyl prints that are sure to impress!

Precision Window Tint Cutting Software for Automotive and Signage Applications

Are you tired of spending countless hours manually cutting window tint film for your automotive or sign shop? Look no further than Tint Tek 20/20, the revolutionary window tint software that streamlines the cutting process and saves you time and money.Unlike traditional methods of cutting window tint film by hand, Tint Tek 20/20 utilizes pre-measured templates that are tailored to specific passenger vehicle models. This ensures a precise and accurate cut every time, reducing waste and eliminating the risk of errors that can occur with manual cutting.But why stop at just accuracy? Tint Tek 20/20 also offers a user-friendly interface that is easy to navigate and can be operated from a personal computer. This allows for increased productivity and efficiency in your shop, as well as providing the flexibility to create custom templates for special requests or unique vehicle types.While there may be other software products on the market for window tint cutting, Tint Tek 20/20 stands out for its robust features and user-friendly design. Plus, with the added convenience of a vinyl cutter, you can quickly and easily produce professional-looking window tint film that will exceed your customers' expectations.But perhaps the best part? Tint Tek 20/20 offers a free window tint cutting software trial, allowing you to test out the program before making a purchase. This means no commitment and no risk - just the opportunity to see firsthand how Tint Tek 20/20 can benefit your shop and simplify your workflow.So why settle for traditional methods of window tint film cutting when you can upgrade to Tint Tek 20/20? Try it out for yourself and experience the convenience, accuracy, and efficiency that this software has to offer.

High-Quality Sticker Cutting Machine for Precision Cuts

Introducing the Latest Innovation: Sticker Cut MachineIn the world of modern technology, advancements are constantly being made to streamline processes and make tasks more efficient. One such innovation that has recently been making waves in the industry is the Sticker Cut Machine, brought to you by {Company Name}. This cutting-edge machine has been designed to revolutionize the way stickers are produced, offering a range of benefits for businesses and individuals alike.{Company Name} is a leading provider of cutting-edge technology solutions, specializing in the development of innovative products that cater to various industries. With a strong reputation for excellence and a commitment to delivering high-quality products, {Company Name} has become a trusted name in the market. Their team of skilled professionals is dedicated to pushing the boundaries of what is possible, and the Sticker Cut Machine is a testament to their innovative spirit.The Sticker Cut Machine is a versatile and user-friendly device that is designed to simplify the process of creating custom stickers. Whether you are a small business looking to produce branded stickers for your products, or an individual looking to create unique designs for personal use, this machine has you covered. With its cutting-edge technology and intuitive interface, the Sticker Cut Machine makes it easy to produce professional-quality stickers with ease.One of the key features of the Sticker Cut Machine is its precision cutting capabilities. Powered by advanced software and state-of-the-art technology, this machine is capable of cutting intricate designs with incredible accuracy. This means that you can create detailed and complex sticker designs without having to worry about any imperfections or inaccuracies. The result is a flawless finished product that is sure to impress.In addition to its cutting capabilities, the Sticker Cut Machine also offers a range of other useful features. For instance, it is compatible with a wide range of materials, including vinyl, paper, and more. This means that you have the flexibility to create stickers in a variety of styles and finishes, depending on your specific needs. Furthermore, the machine is designed to be compact and easy to use, making it suitable for businesses of all sizes and individuals with varying levels of experience.Another notable aspect of the Sticker Cut Machine is its speed and efficiency. Thanks to its advanced technology and high-performance machinery, this device is capable of producing stickers at an impressive rate. This can be a game-changer for businesses that require large volumes of stickers on a regular basis, as it can help to significantly speed up production times and increase overall efficiency.Overall, the Sticker Cut Machine is a game-changing innovation that is set to revolutionize the way stickers are produced. With its precision cutting capabilities, versatility, and user-friendly design, this machine offers a range of benefits for businesses and individuals looking to create custom stickers. Backed by the expertise and reputation of {Company Name}, the Sticker Cut Machine is a product that is set to make a significant impact in the industry.

High-Performance Plotter Cutter Machine for Precision Cutting

Plotter Cutter Machine, is a cutting-edge technology that has revolutionized the way businesses handle their cutting and plotting needs. The machine, developed by a pioneering company in the field of digital fabrication, has become a game-changer in various industries, providing efficient and precise cutting solutions for a wide range of materials.With its advanced features and capabilities, the Plotter Cutter Machine has gained widespread popularity among businesses seeking to streamline their production processes and improve their overall efficiency. The machine is equipped with state-of-the-art cutting technology that allows for precise and accurate cutting of various materials, including paper, cardboard, vinyl, and fabrics. This makes it an ideal solution for businesses in the packaging, signage, and textile industries, among others.The Plotter Cutter Machine is also known for its user-friendly interface and intuitive software, which enables users to easily create and execute cutting and plotting tasks with minimal training or technical expertise. This has made the machine a valuable asset for businesses looking to optimize their production processes and reduce the time and resources required for cutting and plotting tasks.The company behind the Plotter Cutter Machine has a long-standing reputation for innovation and excellence in the field of digital fabrication. With a team of highly skilled engineers and designers, the company has consistently delivered cutting-edge solutions that have set new standards in the industry. The Plotter Cutter Machine is a testament to the company's commitment to providing businesses with the tools they need to succeed in today's competitive market.In addition to its innovative products, the company is also known for its exceptional customer support and service. The company's team of experts is dedicated to providing businesses with the guidance and assistance they need to make the most of their Plotter Cutter Machine. This includes initial setup and training, as well as ongoing technical support to ensure that businesses can continue to take full advantage of the machine's capabilities.The company's commitment to innovation, excellence, and customer satisfaction has made it a leading provider of digital fabrication solutions in the industry. With its proven track record of delivering cutting-edge technology and exceptional service, the company has earned the trust and loyalty of businesses across various sectors.Businesses that have invested in the Plotter Cutter Machine have reported significant improvements in their production processes, as well as cost savings and increased efficiency. By streamlining their cutting and plotting tasks with the help of this advanced technology, businesses have been able to optimize their operations and stay ahead of the competition.As the demand for efficient and precise cutting solutions continues to grow, the Plotter Cutter Machine is expected to play an increasingly vital role in helping businesses meet their production needs. With its advanced technology, user-friendly interface, and exceptional support, the machine is poised to remain a top choice for businesses looking to enhance their cutting and plotting capabilities.In conclusion, the Plotter Cutter Machine, developed by a pioneering company in the field of digital fabrication, has emerged as a game-changing technology for businesses seeking efficient and precise cutting solutions. With its advanced features and capabilities, as well as exceptional customer support, the machine has become a go-to choice for businesses across various industries. As the demand for efficient cutting solutions continues to rise, the Plotter Cutter Machine is expected to play a crucial role in helping businesses optimize their production processes and stay ahead of the competition.

Cutting-Edge PPF Data: A Game-Changer in the Auto Industry

The automotive industry is constantly evolving with new technologies and advancements, and one area that has seen significant development is in paint protection film (PPF). Auto Cut PPF Data, a leading provider of PPF solutions, has been making waves with their innovative products and cutting-edge technology. With a focus on quality and performance, they have established themselves as a trusted name in the industry.Auto Cut PPF Data has been in the business for over a decade, and their experience and expertise have allowed them to push the boundaries of PPF technology. Their commitment to research and development has led to the creation of advanced PPF solutions that offer superior protection and durability. This has made them a go-to choice for automotive enthusiasts and professionals alike.One of the key factors that sets Auto Cut PPF Data apart from the competition is their state-of-the-art manufacturing facilities. Their production process integrates the latest advancements in materials and equipment, allowing them to produce PPF products that meet the highest standards of quality and performance. This dedication to excellence has earned them a reputation for delivering superior results, making them a preferred partner for businesses in the automotive industry.In addition to their commitment to quality, Auto Cut PPF Data also prioritizes customer satisfaction. They understand the diverse needs of their clients and work closely with them to provide customized PPF solutions that meet their specific requirements. Whether it's protecting a luxury vehicle or a fleet of commercial trucks, Auto Cut PPF Data has the expertise and resources to deliver reliable and effective PPF solutions.Furthermore, Auto Cut PPF Data's dedication to innovation has led to the development of a wide range of PPF products that cater to different needs. From self-healing PPF to matte finishes, their diverse product line ensures that customers have access to the latest advancements in PPF technology. This versatility has made them a preferred choice for businesses looking to stay ahead of the curve in the competitive automotive market.As a responsible corporate citizen, Auto Cut PPF Data also places a strong emphasis on sustainability and environmental responsibility. Their manufacturing processes adhere to strict environmental standards, ensuring that their products are not only effective but also eco-friendly. This commitment to sustainability has resonated with environmentally conscious businesses, further solidifying Auto Cut PPF Data's standing as a trusted and reliable partner.Looking ahead, Auto Cut PPF Data continues to lead the way in the PPF industry. Their ongoing investment in research and development ensures that they remain at the forefront of PPF innovation, and their dedication to quality and customer satisfaction sets them apart as a preferred provider of PPF solutions. With a strong track record of success and a commitment to excellence, Auto Cut PPF Data is poised to continue making a significant impact in the automotive industry for years to come.

How to Choose the Best PPF Plotter for Your Needs

Ppf Plotter, a leading provider of plotter machines and printing solutions, has recently introduced a new line of advanced plotter machines that are set to revolutionize the printing industry. With a strong focus on innovation and customer satisfaction, Ppf Plotter has established itself as a trusted name in the industry.The new line of plotter machines is designed to cater to the evolving needs of the printing industry, offering cutting-edge technology and unparalleled performance. These machines are equipped with the latest features and capabilities to ensure high-quality prints with maximum efficiency.With a commitment to delivering superior products, Ppf Plotter has invested heavily in research and development to bring these advanced plotter machines to the market. The company's team of highly skilled engineers and designers have worked tirelessly to integrate the latest technological advancements into these machines, setting new standards for printing quality and speed.One of the key highlights of the new line of plotter machines is the inclusion of advanced software that streamlines the printing process and optimizes workflow. This software allows for seamless integration with existing printing systems, making it easier for businesses to incorporate these machines into their operations. Additionally, the machines are designed to be user-friendly, with intuitive interfaces that make operation simple and efficient.In addition to technological advancements, Ppf Plotter has also focused on enhancing the overall durability and reliability of these machines. The company has used top-quality materials and components to ensure that the plotter machines are built to last. This commitment to quality is a testament to Ppf Plotter's dedication to providing customers with products that deliver exceptional value.Furthermore, Ppf Plotter has also placed a strong emphasis on environmental sustainability. The new line of plotter machines is designed to be energy-efficient, reducing the carbon footprint of printing operations. Additionally, these machines are built to minimize waste and optimize resource utilization, aligning with Ppf Plotter's commitment to eco-friendly practices.With the introduction of these advanced plotter machines, Ppf Plotter is poised to make a significant impact on the printing industry. The company's focus on innovation, quality, and sustainability sets it apart as a leader in the market, and the new line of plotter machines is a testament to Ppf Plotter's dedication to pushing the boundaries of printing technology.The response from the market has been overwhelmingly positive, with industry experts and customers alike praising the new line of plotter machines for its impressive capabilities and performance. Businesses in various sectors, including architecture, engineering, and construction, have already expressed keen interest in integrating these machines into their operations, recognizing the potential to enhance their printing capabilities and streamline their workflow.In conclusion, Ppf Plotter's new line of advanced plotter machines represents a significant leap forward for the printing industry. With its focus on innovation, quality, and sustainability, Ppf Plotter continues to set new standards for printing technology, delivering products that meet the evolving needs of the market. As businesses seek to enhance their printing capabilities, Ppf Plotter's new line of plotter machines stands out as a game-changer, offering unparalleled performance and reliability.

Innovative Window Tint Plotter And Software Revolutionizes Industry

Introducing a Revolutionary Window Tint Plotter and Software SolutionIn today's fast-paced world, technology is constantly evolving to meet the needs of businesses and consumers alike. One company at the forefront of this technological revolution is [Company Name], a global leader in innovative software solutions for the window tint industry. With a dedication to creating cutting-edge products that streamline processes and enhance efficiency, [Company Name] has recently introduced its latest innovation: a state-of-the-art Window Tint Plotter and Software.This innovative solution combines the precision of a high-quality plotter with the advanced capabilities of specialized software, revolutionizing the way window tint is measured, cut, and installed. By seamlessly integrating hardware and software, [Company Name] has created a comprehensive solution that delivers unparalleled accuracy and efficiency, leading to a significant increase in productivity for window tint professionals.The Window Tint Plotter and Software is designed to simplify the entire process of window tint installation, from initial measurements to precise cutting. Utilizing advanced algorithms and innovative design, the software allows users to input precise measurements and specifications, which are then communicated to the plotter. The plotter, equipped with cutting-edge technology, can accurately and efficiently cut tint materials to the exact specifications provided by the software, ensuring a perfect fit for any window.One of the key advantages of this revolutionary solution is its ability to significantly reduce material waste. By eliminating the need for manual cutting and minimizing human error, the Window Tint Plotter and Software optimize the use of tint materials, ultimately leading to cost savings for businesses and a reduced environmental impact.Additionally, the software component of the solution offers a user-friendly interface that can be easily customized to meet the specific needs of individual users. This flexibility allows for seamless integration into existing workflows, while providing the opportunity for further customization and optimization as business needs evolve.Furthermore, the accuracy and precision achieved by the Window Tint Plotter and Software ultimately lead to enhanced customer satisfaction. With perfectly cut and installed window tint, customers can enjoy improved aesthetics, privacy, and UV protection, further solidifying the reputations of businesses utilizing this innovative solution.[Company Name] has a long-standing reputation for delivering top-tier software solutions to the window tint industry. With a focus on innovation and customer satisfaction, the company is committed to providing cutting-edge products that exceed industry standards and expectations. The introduction of the Window Tint Plotter and Software is a testament to [Company Name]'s ongoing commitment to driving efficiency and productivity for businesses within the window tint industry, ultimately delivering value to customers and end-users alike.In addition to the Window Tint Plotter and Software, [Company Name] offers a range of complementary products and services, including training and support, to ensure that businesses can fully leverage the capabilities of their innovative solutions. With a dedicated team of experts and a global network of partners, [Company Name] is well-positioned to provide comprehensive support and assistance to businesses seeking to enhance their operations through technology.As the window tint industry continues to evolve and expand, [Company Name] remains at the forefront of innovation, continually developing new solutions and refining existing products to meet the evolving needs of its customers. With a track record of success and a commitment to excellence, [Company Name] is poised to continue driving positive change within the window tint industry for years to come.In summary, the introduction of the Window Tint Plotter and Software represents a significant milestone for [Company Name] and the window tint industry at large. By combining cutting-edge technology, precision engineering, and user-friendly design, [Company Name] has created a revolutionary solution that promises to streamline operations, improve efficiency, and enhance customer satisfaction for businesses across the globe.For more information about the Window Tint Plotter and Software, as well as other innovative products and services offered by [Company Name], please visit [Company Website].